Our manufacturing facilities & equipment

Star Safety Technologies has been manufacturing LED warning lights, strobe warning lights, lightbars, lanterns, switch controllers, sirens, mounting brackets, and so much more for years.

With decades of industry knowledge on our shoulders, we’re fit to provide all our clients with high-quality lights and sirens for their emergency vehicles, trains, buses, and squad cars.

We’re determined to continue to bring all of you the high standards you’re used to by using the latest technology and techniques in the lighting manufacturing industry.

Take a look at all the amazing equipment and facilities we have that help us bring you the best possible emergency lighting around.

Learn about the history of Star Safety Technologies HERE

- Barlight, LED, Mini-Bar production area

- Plastic molding pellet silos provide ample raw material to meet any change in demand of molded product

- Metal stamping utilizing turret presses for flexibility and short run stamping

- Punch press for larger runs

- Strobes, LED production area

- Surface mount placement equipment (SMT) meeting all the newest board and component designs

- Thru-hole automation insertion equipment

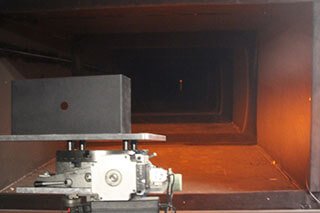

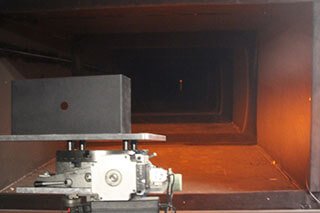

- Light Tunnel: Photometric Validations to SAE standard for LED, Fluorescent, Strobe, Halogen and Incandescent

- Meets the requirements of Automotive, Emergency Equipment, Rail, Industrial Fire Alarms, Certified by AMECA

- EMI Chamber Ability to test our own products to both European and American specifications, in house

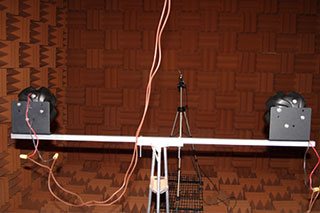

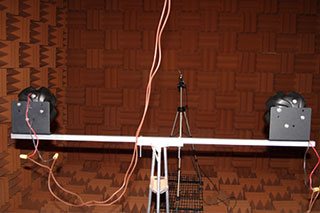

- Anechoic Chamber certified by AMECA to test sound output for sirens, warning alarms and back-up alarms

- Molding in polycarbonate, ABS, Glass Filled Nylon and Over Molding in Polyurethane, Press capability from 80 - 700 tons

- Color Blending capability at the presses, chromaticity validation for color

- Aluminum extrusion, Machining, Cutting, Drilling, and Tapping

- Pad printing machine: Ability to print information directly on products

Core Capabilities

Standard Products

- LED Warning Lights - Beacons, Lightbars, and Directional

- Strobe Lights - Beacons, Lightbars, and Directional

- Halogen/Incandescent - Beacons, Lightbars, and Directional

- Barricade Warning Lights

- Back-Up Alarms, Buzzers, and Sirens

- Railroad Personal Safety Products - Trainman Lanterns, Car Inspector Lanterns, Marker lights, and blue lights

- 6V/12V rechargeable batteries and chargers

- Custom wire harness and Termination

- Mounting Brackets and Assemblies

- LED Illumination Lighting

Design Engineering

Illumination Design Experience

- Source Type: LED, Fluorescent, Gaseous Discharge, Halogen, Incandescent

Audible Products

- Sirens, Back-Up Alarms, Industrial Warning Alarms and Horns

Applications

- Industrial Warning/Emergency Lighting

- Heavy-Duty Truck

- Railroad

- Police

- Fire/EMS

Voltage Ranges

- 6/12/24/36/48/72/120/240V DC 24/120/240V AC, 10-30 10-72/10-110V DC (Multi Voltage)

Modeling/Machine Shop

- 3D Plastic Model Printing

- Plastic Machining

- Metal Machining: Wire EDM, Carbon EDM, CNC Machine and Fabrication of Aluminum Extrusions

- Rapid Prototyping

CAD Capability

- SolidWorks (3-D Mechanical Software), Autocad/Mechanical Desktop (2-D + 3-D) software, TracePro (Optical Ray Trace), Orcad (Schematic/PCB layout), Mastercam (CAD/CAM Software)

Agency Approvals

- UL/CUL [Nema 4X, Explosion proof (Div I, Div 2), IP65, Fire Alarm, Marine]

- CSA, SAE, FRA, CE, California Title 13, AMECA, NFPA, ECE

Test Equipment

- Anechoic Chamber (AMECA Certified), 18 meter Photometric Light Tunnel (AMECA Certified), Environmental Chambers, Electromagnetic and Radio Frequency EMI/RFI Chamber, Dust Chamber

Manufacturing

- Vertically Integrated Metal Stamping, Plastic Molding, Metal Die Fabrication, Plastic Mold Fabrication, Electronic Design and Assembly, Encapsulating, Final Assembly

- Flexible Manufacturing Process Custom Production

- Large Quantity Runs and/or Short Runs

- Inventory management system

- Product Tracing to the End User-Product Serial Number

- Manage via Preventative Maintenance

- Pad printing

Metal Fabrication (Stamping, Bending, Cutting, Welding)

- Stainless Steel to 14 gauge

- Cold Rolled Steel

- Aluminum to 1/4”

- Extrusion CNC

Molding/Over Molding (Polycarbonate, Glass Filled Nylon, ABS, Others)

- 80 - 700 ton molding presses, Color Blending, Chromoticity Testing

Electronic Circuit Boards

- SMT and Thru-Hole, FR-4 and Metal Core

Epoxy Encapsulating

- Weather -Proofing and Vibration Protection

- Urethane and two component epoxy

- Dip, Spray, and encapsulate capability

Internal Design Validation

- AMECA certified Photometric Lab

- AMECA certified Sound Chamber

- ECE Standards

- Solidworks Finite Element Analysis (FEA)

- SAE Standards

- UL/CSA/CE Standards